About Us

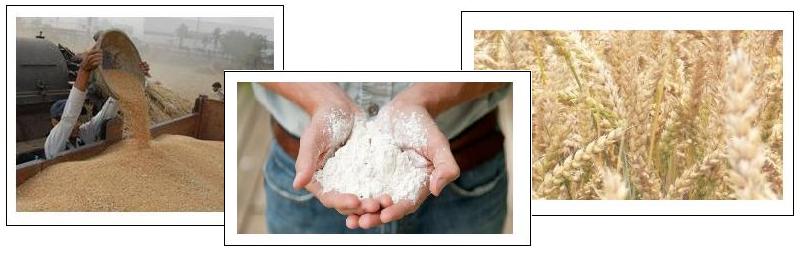

Quality food products require unwavering dedication to quality at every level of our operation – from inspecting wheat and buying it, through transport, storage, processing, packaging and distribution. Our decades of experience in wheat and wheat products have taught us that the journey is a never-ending one - there are always new facts to learn, new practices to implement, and more sophisticated machinery to install. We pride ourselves in being open to learning, willing to change, eager to verify - as long as we believe these efforts will result in higher quality products that are meaningful to our consumers. Recognising that consumer expectations, too, are always changing, a key part of our management effort is to be in constant touch with our customers. Our organization and delivery systems are designed to ensure that this is built into our way of being.

" We Provide Stone Ground Flour "

- Stone ground white flour, however, is somewhat better for you than industrially milled white flour. In a stone mill, whole grain goes in the top and whole grain flour comes out at the bottom. When the miller needs to bag white flour, the whole grain is sifted to separate the three parts of the kernel, leaving the ground endosperm in a bag as white flour. The aim of a stone mill is to produce whole grain flour. In an industrial milling process, grain goes through a series of metal rollers and, during the process, the bran and the germ are swiftly removed and what comes out at the end is white flour. The aim of the industrial milling process is to produce white flour. When an industrial miller wants to bag whole grain flour, a proportion of bran and germ are added back in again. So far so good.